TEADOMER

TEADOMER: Nature’s Eco-Friendly Innovation

Revolutionizing Sustainable Packaging

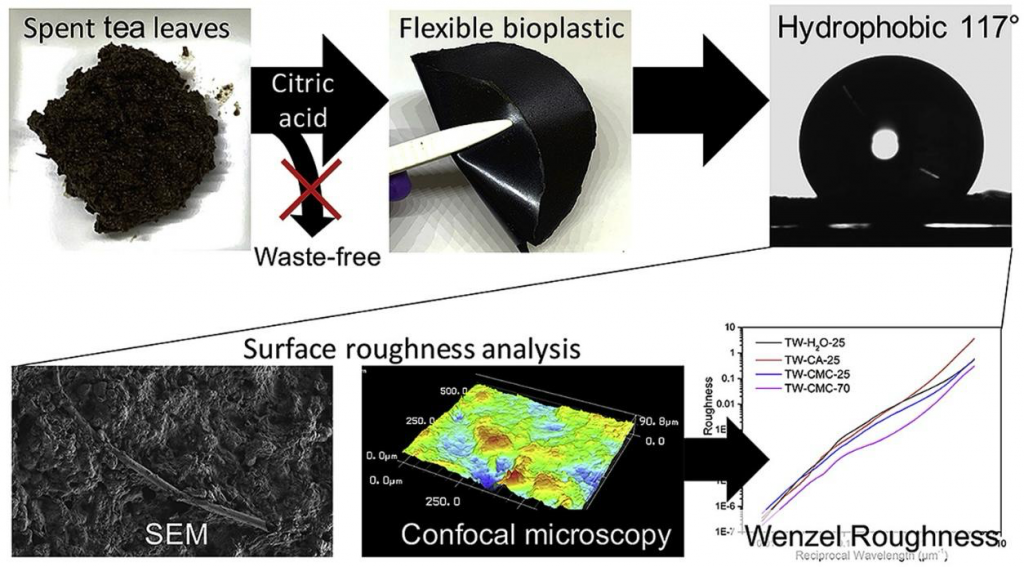

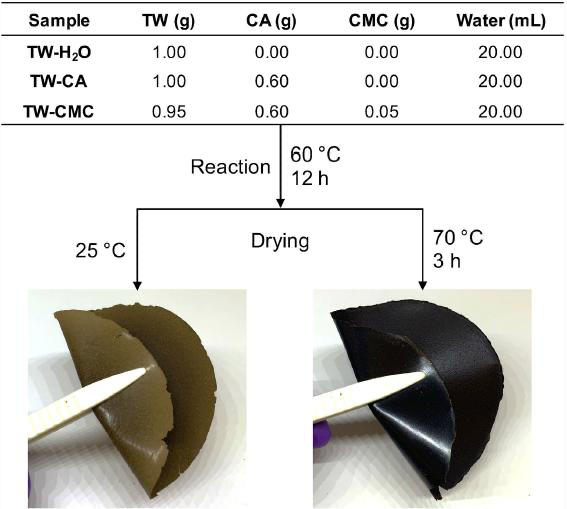

At Seedomer, we are passionate about harnessing nature’s potential to create impactful solutions for a sustainable future. Teadomer is our groundbreaking bioplastic film, ingeniously crafted from spent tea leaves—an industrial byproduct of tea brewing—combined with citric acid and water. This innovative approach minimizes waste and transforms what would otherwise be discarded into a valuable, eco-friendly material.

Key Features:

- 100% Eco-Friendly Composition: Teadomer is made entirely from natural, sustainably sourced ingredients, ensuring it is biodegradable and a perfect alternative to conventional plastics.

- Zero Waste Production: Our state-of-the-art synthesis method generates zero waste, turning tea waste into functional packaging solutions that benefit both the environment and your business.

- Exceptional Hydrophobic Properties: Teadomer boasts remarkable hydrophobic characteristics, achieving a water contact angle of up to 117°. This outstanding feature makes it an ideal choice for packaging applications where moisture resistance is paramount.

- Energy-Efficient Processing: Our production process operates under mild conditions with short processing times, significantly reducing energy consumption and environmental impact.

- Customizable Characteristics: The mechanical strength and hydrophobic qualities of Teadomer can be adjusted based on relative humidity, providing unparalleled versatility for a wide range of applications.

Applications:

- Sustainable Food Packaging: Teadomer is perfect for food packaging, offering a compostable solution that meets the rising consumer demand for environmentally responsible materials.

- Innovative Consumer Goods: From shopping bags to product packaging, Teadomer can seamlessly replace traditional plastics across various sectors, promoting a circular economy.

- Research and Development: As a pioneering material, Teadomer serves as an excellent platform for advancing sustainable practices and innovations in material science.

Be Part of the Change

By choosing Teadomer, you are not just opting for a high-performance, sustainable product; you are actively contributing to a greener planet. Join us in the movement to combat plastic waste and embrace biodegradable materials in our daily lives.

Contact Us today to discover how Teadomer can elevate your business while fostering environmental stewardship!

TEADOMER

Biodegradability of Teadomer

A Sustainable Solution for Our Planet

At Seedomer, we understand that the true measure of sustainability lies in a material’s ability to break down naturally in the environment. Teadomer is designed with this principle at its core, offering a biodegradable alternative to traditional plastics.

Our Research on Biodegradation

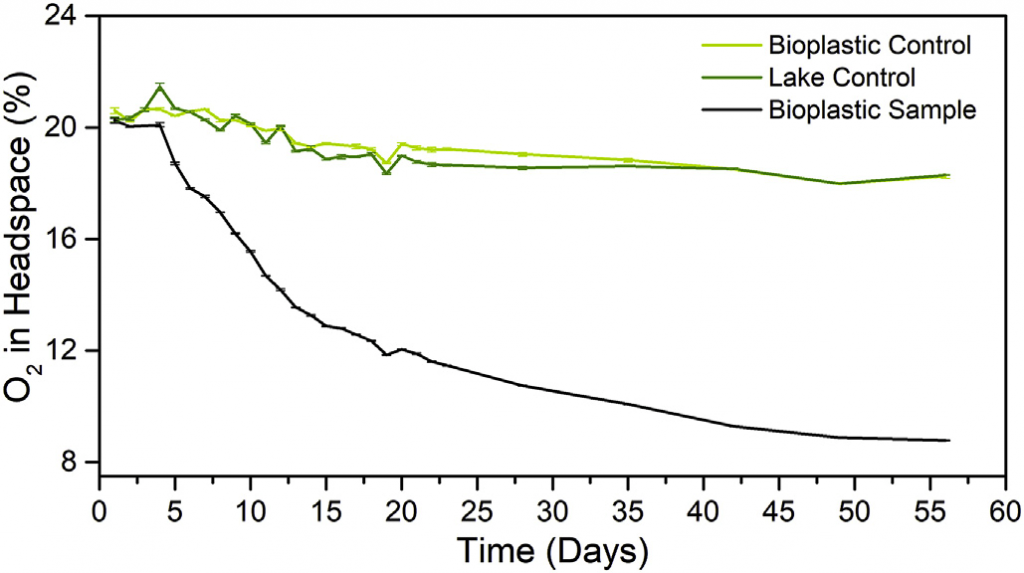

The primary goal of our bioplastics research is to develop materials that are sustainably sourced and degrade easily in natural environments. To model this process, we conducted a study monitoring oxygen levels in the headspace of a closed container, which allowed us to observe the aerobic microbial digestion of Teadomer in lake water.

- Real-World Simulation: In our tests, we evaluated Teadomer as a whole piece rather than pulverized fragments to simulate real-world degradation conditions more accurately. This approach provides a clearer understanding of how Teadomer will behave in nature.

- Control Samples:

- The “Bioplastic Control” sample contained Teadomer in deionized water, allowing us to measure the bioplastic’s non-microbial depletion of oxygen.

- The “Lake Control” sample contained only lake water to account for any background aerobic activity occurring in the environment.

Observations and Findings

Our research showed that microbial consumption of oxygen due to the degradation of Teadomer begins after several days of immersion in lake water. The oxygen depletion observed in the Teadomer sample was more significant than the sum of the oxygen depletion from both control samples, indicating active aerobic microbial activity resulting from the decomposition of the bioplastic film.

Commitment to a Greener Future

Teadomer represents a significant step toward more sustainable packaging solutions. By ensuring that our bioplastic films reduce waste and biodegrade efficiently in natural environments, we contribute to a cleaner, healthier planet.

Choose Teadomer for your packaging needs, and join us in promoting environmental stewardship through innovative, sustainable practices.